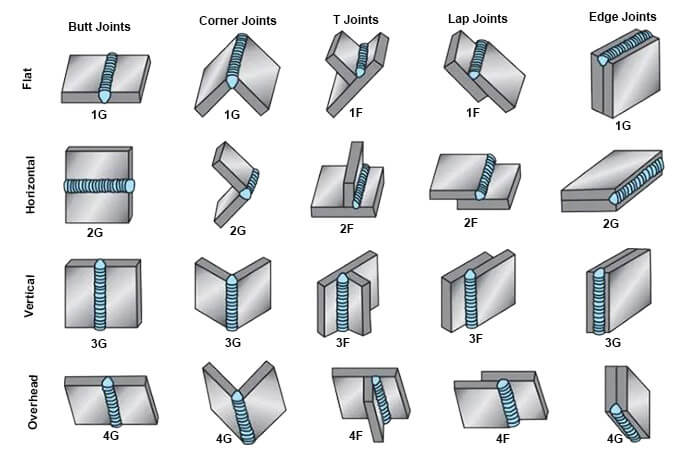

Welders with training and experience are expected to have mastered various Welding Positions. These are basically the different angles of joining metals. Normally, there are four types of welding positions namely horizontal, flat, vertical, and overhead. And the most common types of welds are groove and fillet welds. Welders can perform these two welds in all four positions. Besides this, there are special letters to designate fillet and groove welds.

Fillet Weld (F) – It is a welding method for combining two parts of metal vertically or slightly at an angle.

Groove Weld (G) – It is a weld made in the groove. It requires full penetration for laying strong welds.

Groove and Fillet Welding Positions

Normally, the following numbers and letters are used.

For groove welding positions-

- 1G – (flat welding position)

- 2G – (horizontal welding position)

- 3G – (vertical welding position)

- 4G – (welding position overhead or overhead)

- 5G – (uphill/downhill vertical welding position)

- 6G/6GR – (overhead vertical welding position)

For fillet welding positions-

- 1F – (flat welding position)

- 2F – (horizontal welding position)

- 3F – (vertical welding position)

- 4F – (welding position overhead or overhead)

For a welder to perform certain tasks , they need to provide proof of training in all the relevant welding positions up to position 6G. The EA Institute of Welding provides individual up skilling training for welders after an initial assessment of the welder capabilities on different positions. We then give weekly trainings to the individual to be able to perfect the weld test sample for a Certificate of competence.